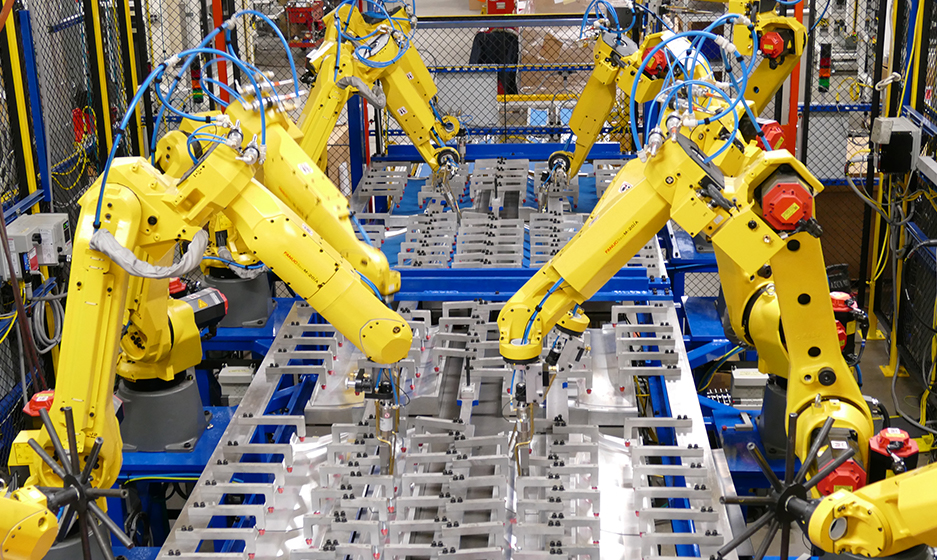

CUSTOM DESIGN AND AND SPECIAL PURPOSE MACHINES (SPM)

Special Purpose Machines, commonly known as SPM machines, are mostly unavailable off the shelf. Unlike other machines, these don’t fall in the category of standard manufacturing programs. These machines are specially designed and tailored as per one’s specific demand. SPMs are also known as bespoke machines and specially designed machines.

Also, as the name suggests, special purpose machines are crafted to deal with special tasks such as fulfilling mass demands, producing materials with complete automation and so on. In this blog, we will help you know the usage and working of SPM machine, followed by some real example of SPMs. Towards the end, we will also tell you some advantages and disadvantages of these machines.

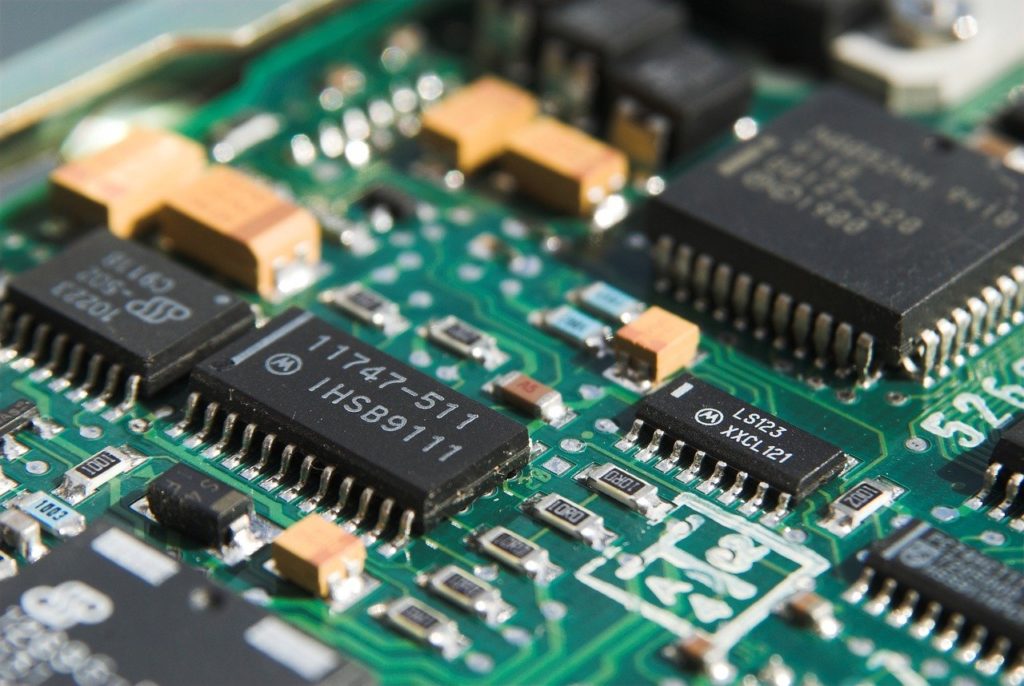

These machines can be used for operations such as drilling,

tapping, rough boring, fine boring, reaming, and spot facing. Mostly

facing and centering machines are available in both vertical and horizontal

configurations with slides for plunge or traverse milling.

These include Multi Spindle Drilling Machines, Muilti Spindle Milling, tapping, boring, reaming. The purpose of these machines is to do multiple operations on a component in one setting.